Over the years, steel cylinders are subjected to the stresses of rough and intensive handling, as well as environmental conditions, resulting in deformation, twisting, and rust due to surface abrasion.

These cylinders require regular monitoring and inspection at intervals adapted to the specific environmental and handling conditions of each market.

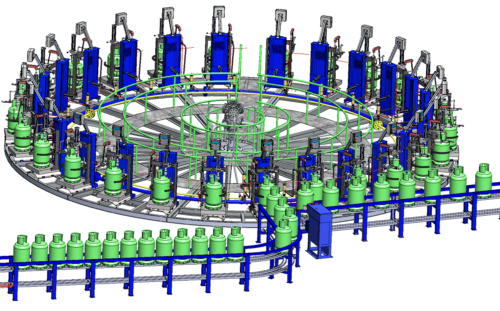

Kaya offers a complete range of hot repair equipment for LPG cylinders that cannot be repaired by the top or bottom ring straighteners on its scales, due to the severe deformation of these rings. This range also includes accessories for cutting and surface welding of caps and bottom rings, as well as equipment for standardizing LPG cylinders.

• Obtain bottles in perfect condition and with high market value

• Avoid production downtime due to damaged caps and end caps

• Achieve significant cost savings by reducing the number of bottles required

• Assembly of complete workstations for cutting and welding