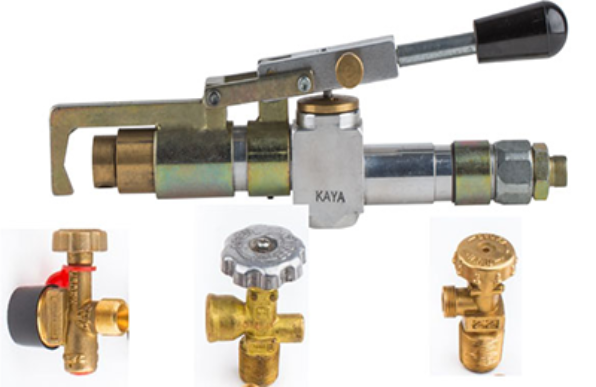

Filling Heads:

Robust, high-quality systems, the result of 45 years of experience.

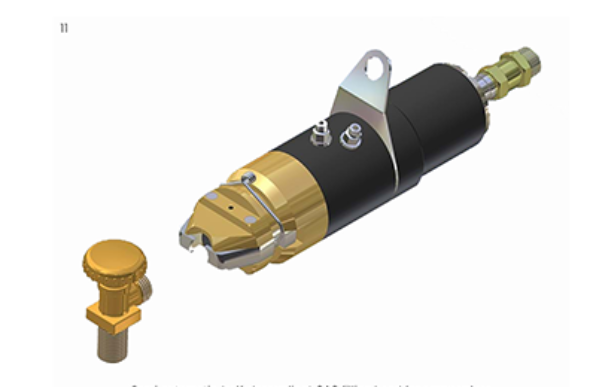

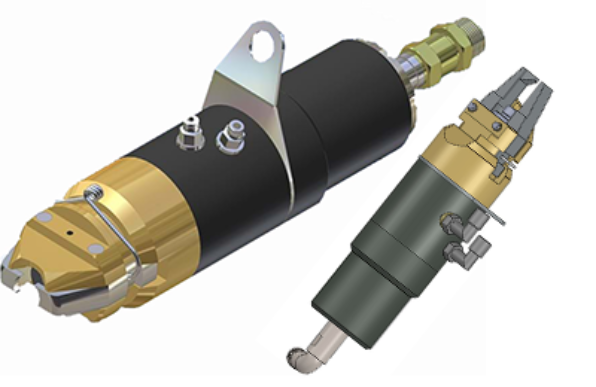

Kaya LPG filling heads are designed to fit various types of cylinder valves.

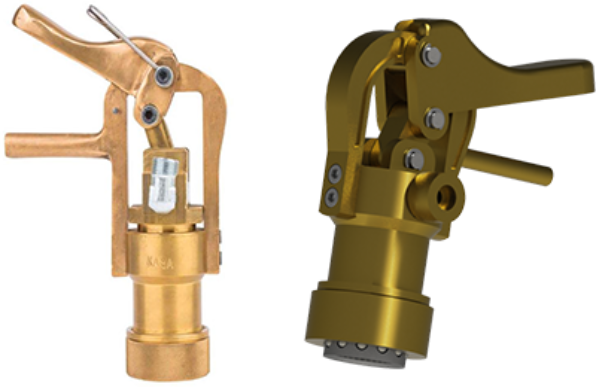

They can be manual or automatic pneumatic, depending on the customer's needs.

Made of brass, the filling heads meet explosion-proof standards.

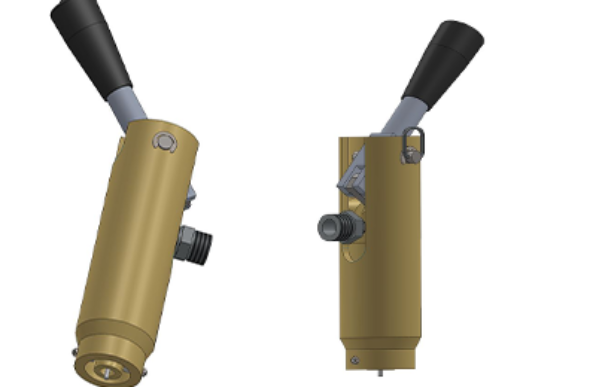

Manual LPG Filling Heads:

Made from corrosion-resistant materials such as stainless steel, brass, aluminum, and special polymers.

Balanced support for easy suspension between filling operations.

Easy connection and disconnection. Filling is initiated by operating the manual handle.

Compact design facilitates handling and integration into any type of enclosure.

Operation: Fully automatic, semi-automatic, or manual

High safety level

Can be used for both filling and evacuation

Optimized flow and filling speed

Filling heads for all types of center and screw valves

Custom-specific filling heads for special valves

Use in combination with a wide variety of filling machines

Advantages

Operation: Fully automatic, semi-automatic, or manual

High safety level

Suitable for filling and emptying

Optimized flow and filling speed

Filling heads for all types of center and screw valves

Custom-made filling heads for special valves

Compatible with a wide range of filling machines

Advantages

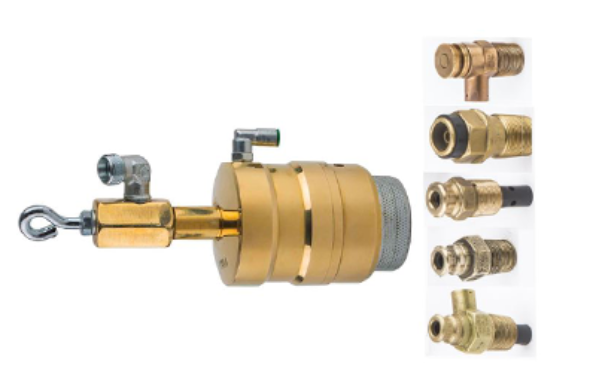

Quick and easy coupling and uncoupling

Minimal gas release during coupling and uncoupling

No gas release in case of compressed air failure

Manual and semi-automatic filling heads are operated with one hand

Flexible suspension for coupling off-center valves during filling

Use Ergonomic manual and semi-automatic filling heads thanks to balanced suspension

Minimal maintenance

Workplace safety:

Ex marking according to the ATEX directive and applicable EN standards: II 2G Ex h IIA T4 Gb CE marking EX marking

All equipment and machines are designed to operate in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 80079-36:2016. All equipment and machines are designed and certified in accordance with an ISO 9001 certified quality management system; furthermore, they are designed in accordance with all relevant requirements set out in applicable European directives.